*Product advantages:

High temperature resistance, oil-free bearing with double support, double spherical seal, automatic centering automatic compensation,

reduce friction, long life and high reliability, reduce the number of downtime.

*Range of adaptation:

Maximum speed: ≤100RPM

Maximum temperature: ≤340℃

Maximum pressure: ≤ 1.8mpa

Applicable medium: saturated steam, superheated steam, superheated water

*Product features:

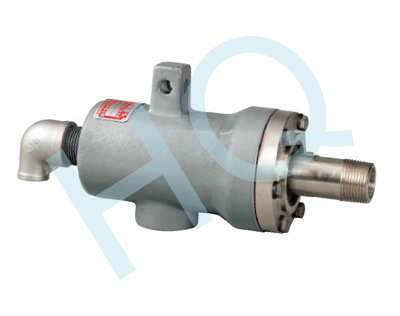

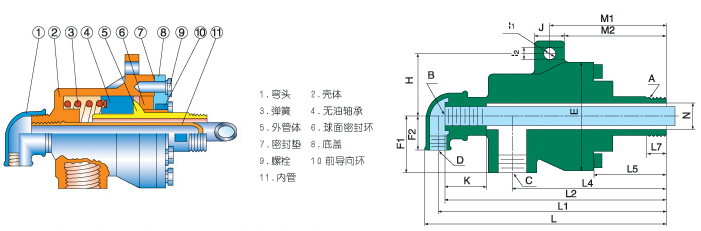

QS-G special rotary joint for high temperature heat conduction oil is generally used as the main rotating part of the equipment, directly

connected to the drying cylinder or roller. This product USES the precision machining outer tube body sphere, the bottom cover and

the sealing ring to constitute the dynamic seal friction pair, the reliability is high. The spherical sealing ring can slide in the space composed of the outer tube surface and the bottom cover. This product can be freely supported internally, oil-free bearing and shell are tightly combined, there is no high precision requirement when installing. After the rotary joint works for a long time, the spherical seal ring will wear out.

At this time, the pressure of the spring can be compensated. After compensation, the shell will move backwards. When the rotary joint

works, the medium is covered with a layer of liquid film on the spherical sealing ring and oil-free bearing, which can not only increase

the sealing performance, but also improve the lubrication and increase the service life of the product.

RYQS-G Details———————————————————————————-

| Model | A | B | C | E | F1 | F2 | H | l1 | l2 | J |

| RYQS-G20-8 | R3/4 | G1/4 | RC3/4 | 96 | 49 | 30 | 53 | 12 | 12 | 25 |

| RYQS-G25-10 | R1 | G3/8 | RC3/4 | 98 | 56 | 40 | 65 | 12 | 12 | 25 |

| RYQS-G32-15 | R1-1/4 | G1/2 | RC1 | 120 | 68 | 38 | 78 | 14 | 14 | 30 |

| RYQS-G40-20 | R1-1/2 | G3/4 | RC1-1/4 | 130 | 80 | 43 | 80 | 14 | 14 | 32 |

| RYQS-G50-25 | R2 | G1 | RC1-1/2 | 160 | 94 | 51 | 90 | 14 | 14 | 36 |

| Model | K | L | L1 | L2 | L4 | L5 | L7 | M1 | M2 | N |

| RYQS-G20-8 | 30 | 245 | 228 | 222 | 144 | 50 | 20 | 144 | 132 | 18 |

| RYQS-G25-10 | 31 | 285 | 270 | 257 | 169 | 61 | 22 | 169 | 157 | 24 |

| RYQS-G32-15 | 34 | 312 | 298 | 289 | 192 | 65 | 26 | 206 | 176 | 30 |

| RYQS-G40-20 | 40 | 350 | 332 | 320 | 210 | 70 | 30 | 210 | 194 | 38 |

| RYQS-G50-25 | 50 | 416 | 395 | 378 | 242 | 80 | 30 | 260 | 242 | 48 |

Application Case ————————————————————————————-