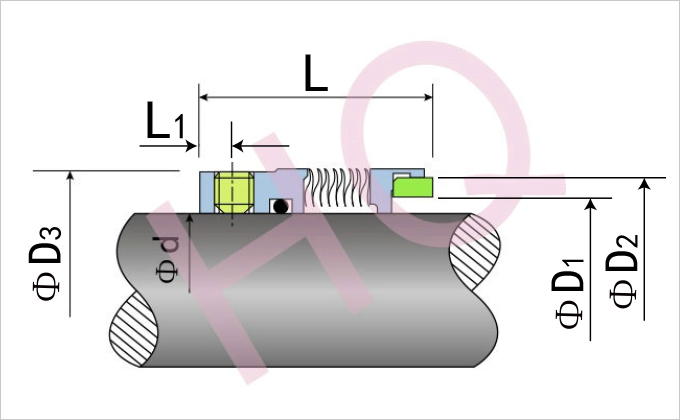

| d(mm) | D1 | D2 | D3 | L | L1 | Set Screw Size/Qty |

| 24 | 29.79 | 34.93 | 38.10 | 30.0 | 4.5 | M5X3 |

| 25 | 30.50 | 35.68 | 39.00 | 30.0 | 4.5 | M5X3 |

| 28 | 33.50 | 38.68 | 42.00 | 32.5 | 5.5 | M5X3 |

| 30 | 35.50 | 40.68 | 44.00 | 32.5 | 5.1 | M5X3 |

| 32 | 38.51 | 43.66 | 46.02 | 32.5 | 5.1 | M5X3 |

| 33 | 38.20 | 44.63 | 47.00 | 32.5 | 4.5 | M5X3 |

| 35 | 41.68 | 46.86 | 49.20 | 32.5 | 4.5 | M5X3 |

| 38 | 43.59 | 50.04 | 52.37 | 34.0 | 5.2 | M6X3 |

| 40 | 46.76 | 53.21 | 55.55 | 34.0 | 5.2 | M6X3 |

| 43 | 49.94 | 56.39 | 58.72 | 34.0 | 5.2 | M6X3 |

| 45 | 49.94 | 56.39 | 58.72 | 34.0 | 5.2 | M6X3 |

| 48 | 53.09 | 59.56 | 61.90 | 34.0 | 5.2 | M6X3 |

| 50 | 56.29 | 62.76 | 65.07 | 34.0 | 5.2 | M6X3 |

| 53 | 59.44 | 65.91 | 68.25 | 34.0 | 5.2 | M6X3 |

| 55 | 62.00 | 68.45 | 71.00 | 34.0 | 4.6 | M6X3 |

| 58 | 65.79 | 72.29 | 74.60 | 39.5 | 6.6 | M6X3 |

| 60 | 65.79 | 72.29 | 74.60 | 39.5 | 6.6 | M6X3 |

| 63 | 70.87 | 78.64 | 80.95 | 39.5 | 6.6 | M6X3 |

| 65 | 74.04 | 81.81 | 84.12 | 39.5 | 6.0 | M6X3 |

| 70 | 77.22 | 85.01 | 87.30 | 45.0 | 8.2 | M6X3 |

| 75 | 84.38 | 92.13 | 95.25 | 45.0 | 7.8 | M6X3 |

| 80 | 87.3 | 95.81 | 98.43 | 44.5 | 6.7 | M6X4 |

| 85 | 93.65 | 102.16 | 104.78 | 44.5 | 6.7 | M6X4 |

| 90 | 96.82 | 105.33 | 107.95 | 49.5 | 9.0 | M6X4 |

| 95 | 103.17 | 111.68 | 114.30 | 49.5 | 9.0 | M6X4 |

| 100 | 109.52 | 118.03 | 120.65 | 49.5 | 9.0 | M6X4 |

| Dash No. | d(inch) | D1 | D2 | D3 | L | L1 | Set Screw Size/Qty |

| 16 | 1.000 | 1.235 | 1.439 | 1.562 | 1.250 | 0.17 | 10-24×3 |

| 18 | 1.125 | 1.362 | 1.566 | 1.687 | 1.250 | 0.17 | 10-24×3 |

| 20 | 1.250 | 1.516 | 1.720 | 1.812 | 1.312 | 0.17 | 10-24×3 |

| 22 | 1.375 | 1.641 | 1.846 | 1.937 | 1.437 | 0.2 | 1/4-20×3 |

| 24 | 1.500 | 1.716 | 1.971 | 2.062 | 1.437 | 0.2 | 1/4-20×3 |

| 26 | 1.625 | 1.841 | 2.096 | 2.187 | 1.437 | 0.2 | 1/4-20×3 |

| 28 | 1.750 | 1.966 | 2.221 | 2.312 | 1.437 | 0.2 | 1/4-20×3 |

| 30 | 1.875 | 2.09 | 2.346 | 2.437 | 1.500 | 0.22 | 1/4-20×3 |

| 32 | 2.000 | 2.216 | 2.472 | 2.562 | 1.500 | 0.22 | 1/4-20×3 |

| 34 | 2.125 | 2.340 | 2.597 | 2.687 | 1.500 | 0.22 | 1/4-20×3 |

| 36 | 2.250 | 2.466 | 2.723 | 2.812 | 1.562 | 0.22 | 1/4-20×3 |

| 38 | 2.375 | 2.590 | 2.848 | 2.937 | 1.562 | 0.22 | 1/4-20×3 |

| 40 | 2.500 | 2.790 | 3.098 | 3.187 | 1.562 | 0.22 | 1/4-20×3 |

| 42 | 2.625 | 2.915 | 3.223 | 3.312 | 1.625 | 0.22 | 1/4-20×3 |

| 44 | 2.750 | 3.040 | 3.349 | 3.437 | 1.625 | 0.22 | 1/4-20×3 |

| 46 | 2.875 | 3.196 | 3.504 | 3.625 | 1.687 | 0.22 | 1/4-20×3 |

| 48 | 3.000 | 3.322 | 3.629 | 3.750 | 1.687 | 0.22 | 1/4-20×3 |

| 50 | 3.125 | 3.437 | 3.774 | 3.875 | 1.750 | 0.22 | 1/4-20×3 |

| 52 | 3.250 | 3.562 | 3.899 | 4.000 | 1.750 | 0.22 | 1/4-20×3 |

| 54 | 3.375 | 3.687 | 4.024 | 4.125 | 1.750 | 0.22 | 1/4-20×3 |

| 56 | 3.500 | 3.812 | 4.149 | 4.250 | 1.875 | 0.22 | 1/4-20×3 |

| 58 | 3.625 | 3.937 | 4.274 | 4.375 | 1.875 | 0.22 | 1/4-20×3 |

| 60 | 3.750 | 4.062 | 4.399 | 4.500 | 1.875 | 0.22 | 1/4-20×3 |

| 62 | 3.875 | 4.187 | 4.524 | 4.625 | 1.875 | 0.22 | 1/4-20×3 |

| 64 | 4.000 | 4.312 | 4.649 | 4.7500 | 1.875 | 0.22 | 1/4-20×3 |

* The product description:

The type 670 is a full Harcourt C rotary bellows seal. It is extremely durable and reliable

in a wide range of temperature and media applications. The type 670 seal has passed the

standard inspection of API682B seal and is suitable for low temperature conditions in

the oil refining industry. Other common uses include acids, amines, water containing sulfur,

and hydrocarbons containing hydrogen sulfide.

The type 670 can be designed with double face seal with no pressure buffer or pressure

isolator to maintain circulation of isolator through pump ring to ensure relatively low

operating temperature and durable and reliable performance. To meet more stringent

environmental and safety control requirements, the seal is available with dry operation

YTS-

The type 675 and 676 seals have the same superior performance as the type 670 seals,

only with different combinations of materials. Titanium bellows type 675 are ideal for

sealing with chlorine, ferric chloride, caustic soda and other media. type 676 of AM350

stainless steel bellows is suitable for slightly corrosive and abrasive media, such as various

water and papermaking materials.

* Material:

Bellows:

670:HAstelloy-C

675:Titanim

676:AM350

680:Alloy 20

Metal Parts:

670:HAstelloy-C

676:AISI316L

680:300 series stainless steel.